The Old Car Files: Failure to Start

It's time for another installment in the Old Car Files series. This week, the old Element treated me to a guessing game I like to call "Why won't you start?". The game began on Monday night around 8:30 as I was trying to leave my son's Boy Scout meeting. The engine attempted to start but died immediately. After that it wouldn't even crank at all. It just made a little buzzing sound. My natural first thought is a battery problem, though a few clues did not support that theory. For one, the headlights and electronics all seemed to work fine, and there was no weak crank attempt. Since I wasn't too far from home, I called Mrs. Wisdom to bring a battery pack for jump starting. We hooked that up and it still wouldn't crank. So, we tried jumping it directly from her car. Still nothing. Maybe her old Prius doesn't have enough juice to jump the Element.

At this point, some nice men were leaving a meeting at the church parking lot where all this was going down. Several of them offered to help (after the obligatory dad jokes about car repair merit badges 😄)- we tried jumping the E with one of their trucks and another car, but nothing worked. At this point we were all pretty sure it couldn't be the battery. The starter was the next thought. We pulled the lower panel from the car and could just make out the starter. We gave it a few love taps with a hammer to see if we could un-stick anything that might be stuck. No luck. It's about 9:30 at this point, so it was time to call it a night. We left a note on the car saying it wouldn't start and left it in the parking lot.

I had to go to work the next morning (thankfully I keep a spare car around) so Mrs. Wisdom started arranging a tow. Unfortunately, the church was having some work done installing a power line underground for a new solar array in the back of their parking lot, and guess who's car was sitting right in the way of where they needed to dig?! Luckily, AAA was fast and responsive and able to tow the car back to our house without delaying the parking lot work too long.

The tow truck dropped the car in the driveway, so when I got home from work, I needed to get the car into the garage where I could work on it. This wouldn't have been too hard if our driveway were flat into the garage. We could just push it in. Instead, we need to negotiate a slight uphill and do a 3-point turn to align it with the garage bay. So, I came up with either a great or stupid idea: use my lawnmower to pull the car! It's a great idea if it works and a stupid idea if it destroys my mower.

I got an electric zero turn lawnmower a few years ago. The electric motors have lots of torque, so I thought it might be able to pull the car up the hill. Mrs. Wisdom got in the E to steer and got a workout wrestling the wheel around without power steering. The lawnmower did well, though I could feel it struggling at the last little lip into the garage. I'll call it a win- the Element was now in the operating room and I didn't break anything on my mower.

Now for a brief aside about car designers. What a bunch of jerks! I think they intentionally design the vehicle to give mechanics high blood pressure.

The starter for the element is not really serviceable from the bottom of the car. Or the top. If you go through the bottom, you have a blind bolt that you can't see and have no room get any leverage on a wrench. Some people have managed to change out the starter this way, but none of them have rusty, twenty year old Elements. I decided to go the top route, which involves taking out a crossbar and wiring harness followed by removal of the intake manifold and throttle body.

Here's the disassembly to create a hole to even get to the starter.

Doing this at least exposed the bolts and connectors that I needed to remove. It seems like half the bolts in this process are blocked by some bracket or wire that you first have to remove before you can take off the bolt you want. It's like some heinous Rube Goldberg contraption. No thought was given to serviceability on this vehicle, particularly when it gets older and bolts need breaker bars or impact wrenches to free them. Then there are the stupid plastic trim tabs that would rather break than be removed. Grrr.

After a couple hours, the starter is exposed enough to get wrenches on all the bolts. Great, except I can't loosen them. There isn't enough space to move a breaker bar. My impact wrench is too large to get down into the cavity and my air ratchet isn't powerful enough to loosen the bolts. I hit them with penetrating oil and eventually was able to break them loose with the ratchet. Still the starter won't come loose. 20 years of galvanic corrosion has welded it to the engine case. It took 10 minutes of pounding on it from every side I could with a crowbar and hammer combo before it started to release its grip.

Hole where the starter was:

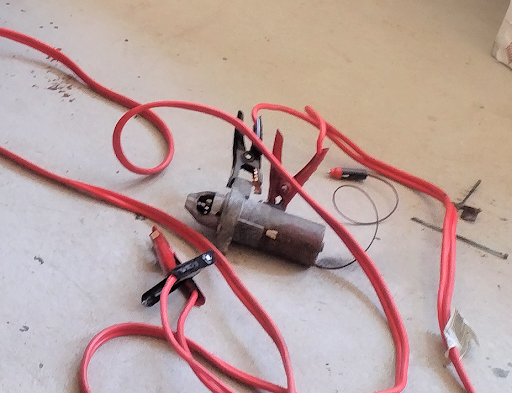

I test the starter directly on the battery and find it works.

Now what? Either it wasn't the problem, or the beating it took to remove from the car un-stuck it. I figure since it was pretty rusted and two decades old, I should replace it anyway while I have the car apart. A new Honda OEM starter was nearly $500. That isn't going to happen. Cheap aftermarket starters can be had for as little as $80. Reviews on the Element Owners Club are less than stellar for them, however. I settled on a remanufactured Denso brand (at least a reputable name and OEM for some parts) for a little under $200 available the same day at Napa Auto Parts.

New starter goes in. Intake manifold goes back on. Key gets turned. And... nothing. No crank. Ok, maybe I need to finish reconnecting the wiring harness stuff in case it needs to see all those sensors before it starts. Get that all back together and it still won't crank.

Back to the drawing board. Next area of focus is the ignition system. More cursing of the car designers: the relay/fuse box with the ignition stuff is in the footwell of the drives seat. It's hard enough to get in there to look at anything, but they also put a bunch of wiring harnesses in front of the panel so even if you can get your head under there to see it, the view is blocked by wires.

It takes a couple hours of internet searching and knee/back killing contorting to locate and remove the ignition cut relay for testing. I test it, and it appears to work fine. I use my voltmeter to test all the terminals on the panel and observe them to function correctly. Power is in the right spots when I turn the key. The transmission lockout is grounding the terminal appropriately. It makes no sense- everything should work. I thought perhaps a frozen engine could cause this, but when I had the starter out I used a screwdriver to turn the gear the starter operates on and could turn it, so the engine didn't seem frozen.

That leaves wiring as really the only remaining place where the problem could be. I start at the battery. I had seen the negative wire run over and get bolted to the chassis, but there was a second pigtail on it. I follow it down and see it connecting to the engine block. But it doesn't look right. It is a fat, 6 gauge wire, but at the terminal on the engine block the exposed copper is all green with oxidation. Even more suspicious is a bunch of the strands are broken at the ring connector only leaving a few strands connected. Could this be the problem? There is electrical connectivity, but it is probably a somewhat higher resistance at the high currents the starter requires. The engine mounts must isolate the engine from the chassis electrically so that this wire is the only return path for the starter. Nobody has a new negative wire cable in stock around me, so I get to work jury rigging a way to beef up that connection. With that connection more robust, I put the battery back in and the car starts right up! It was that weak connection all along.

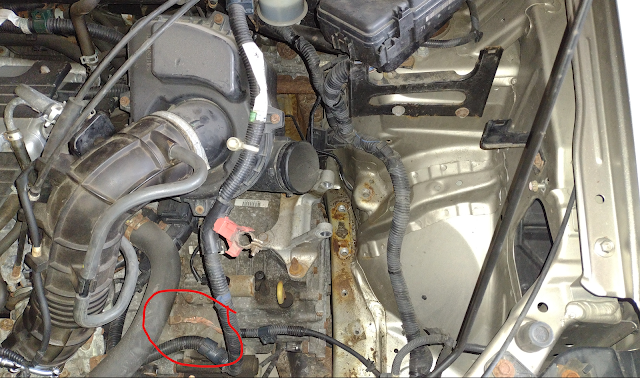

Here is my repaired lead circled in red in the photo below. I basically knocked off the oxidation, pried open the clamp area of the ring connector and shoved more strands of wire in and used pliers to re-clamp it. (Note: This is shown with the intake, battery and battery tray removed for access as well as the transmission mount for replacement).

That is where things stand today. I am now waiting on parts- a new negative battery harness and a transmission mount. I had a suspicion that the transmission/motor mount in the area of that cable may have been going back causing excessive movement of the engine which led to the wire breaking. Old transmission mount:

I believe the gap at the top is intentional and not a broken bushing, so I don't think this mount is as bad as it looks, but it is still 20 years old, and the rubber could probably do with being replaced.

So, a new mount is coming along with a new battery cable (inexpensive stuff from Rock Auto). I also had to take the intake off again and put a new gasket on that I didn't have at the time. It was a lot quicker the second time around. I have the old motor mount off already, so installation should be pretty quick when the parts arrive, and it didn't require all that much disassembly to access; I only had to remove the battery, battery tray, air intake and fuse box. There was enough room for breaker bars for this job.

I am on the fence about whether I regret changing the starter or not. I can't really call it a lesson learned, because there isn't really a way to test the starter without disassembling half the engine bay to get at it. It's a couple hundred bucks that I might never have needed to spend. Or, maybe it was worth it if the original starter was going to go bad soon anyway. All in all, this was a decent learning experience and good bonding exercise for me and the E. The amount of bloodshed was low, just a few scrapes and abrasions all up my arms from reaching so deep into the engine bay. The total cost for the repair was pretty reasonable, at least since my labor was free. Now, who wants to bet on what fails next?

Comments

Post a Comment